RESEARCH

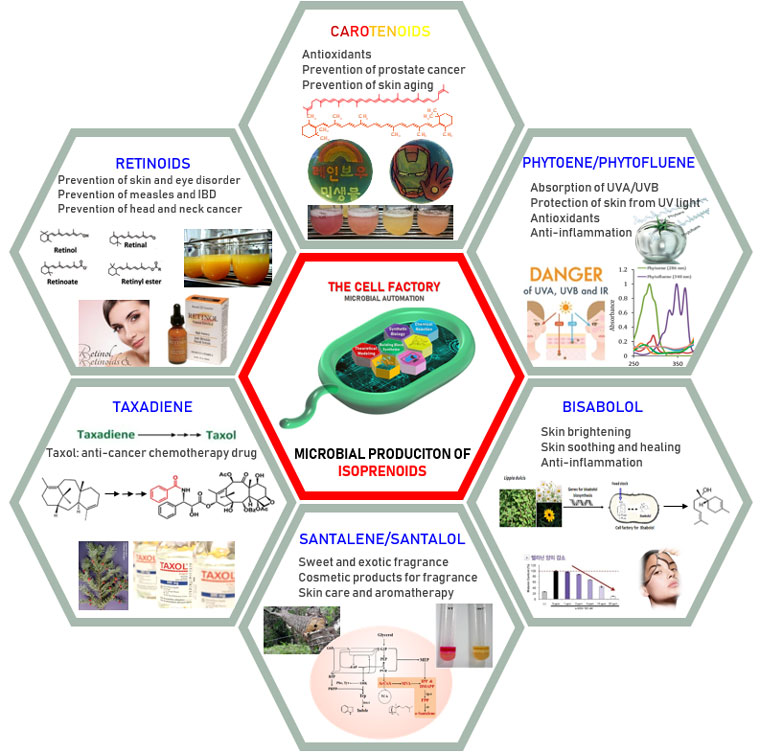

Functional Isoprenoids

Isoprenoids are the most chemically diverse compounds found in nature. They are present in all organisms and have essential roles in membrane structure, redox chemistry, reproductive cycles, growth regulation, signal transduction and defense mechanisms. Advantages of microbial production of carotenoids include the ability of microorganisms to use low cost substrates, the optimized control of cultivation, minimized production time and the process can be economically scaled-up.

- Carotenoids are a diverse class of C40 isoprenoids with multiple physiological and nutritional roles in plants, algae, bacteria, and fungi. Several carotenoids such as lycopene, β-carotene, zeaxanthin, and astaxanthin are important industrially as nutrient supplements, food colorants, and feed additives. Scientific interest in dietary carotenoids has increased in recent years due to their beneficial effects on human health, such as a reduced risk of cancer and enhancement of immune system function, which are attributed to their antioxidative potential.

- Phytoene/Phytofluene are key tetraterpene (C40) carotenes formed at the first committed step in carotenoid syntheses. In contrast to other carotenoids, phytoene/phytofluene are colorless and absorb UV-B/UV-A light, which can be used as a photo-protective material to prevent urban skin aging.

- Retinoids are a class of lipophilic isoprenoid molecules that are related chemically to vitamin A. Retinoids are composed of a β-ionone ring and a polyunsaturated side chain, with an alcohol (retinol), an aldehyde (retinal), a carboxylic acid (retinoic acid), or an ester (retinyl esters) functional group. They play an essential role in vision, bone development, reproduction, and skin health as antioxidants and are also known to reduce the risk of certain cancers.

- α-Bisabolol is a natural-occurring sesquiterpenoid with applications in cosmetics as brightening and soothing agent.

- Taxadiene is the first committed intermediate in the synthesis of taxol. Taxol is a potent and widely used antitumor agent isolated from the bark of the pacific yew tree.

- Santalene is a major component of Sandalwood oil. Sandalwood oil is known for its pleasant woody and sweet aroma, so it has been used in perfumes, cosmetics, ointments, and physical and mental therapy.

Keywords : Microbial Cell Factory, Isoprenoids, Carotenoids, Phytoene/Phytofluene, Retinoids, Bisabolol, Taxadiene, Santalene

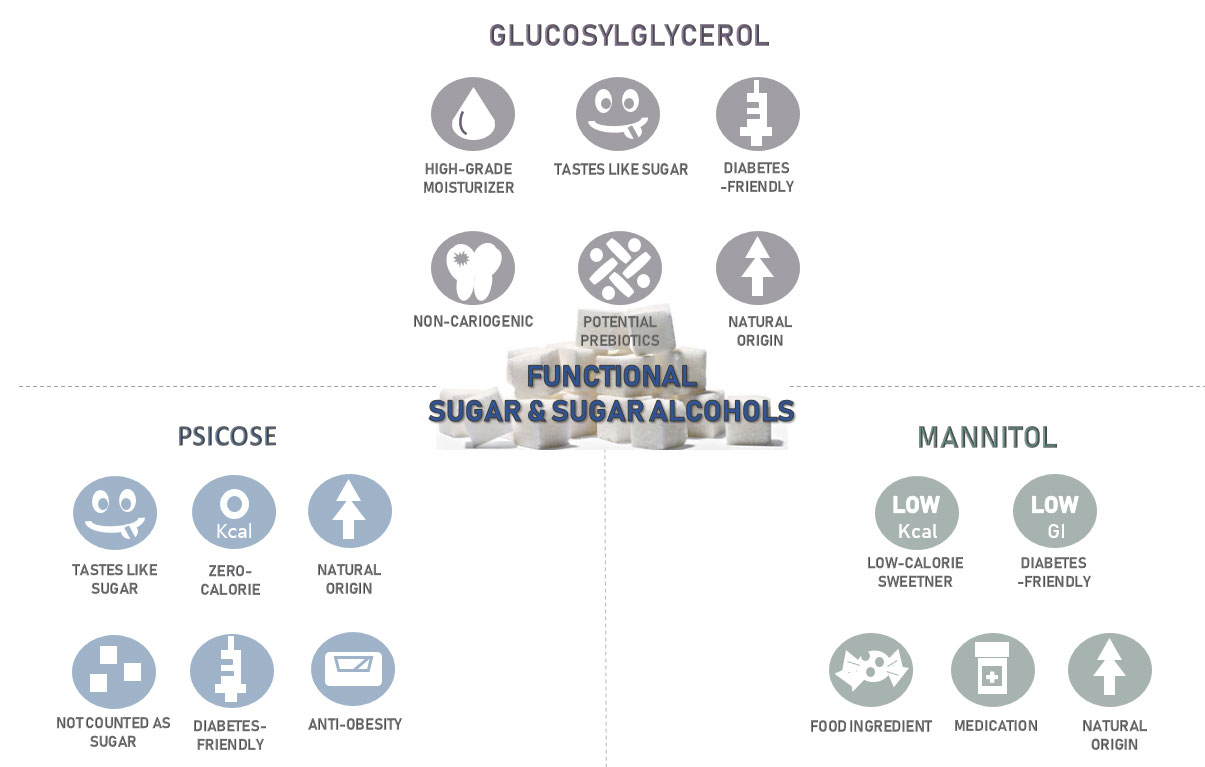

3rd Generation Sugars and Sugar Alcohols

Sugars are easily found and abundant in nature. It has important roles in organisms as a background of body, fuel, energy storage, and sparing of protein as well as properties in food as enhancer of tastes, aromas, weight, volume, texture, and color. Recently, besides that, some sugars have been revealed for their various biological functions like ultra-low calorie sweetener, anti-diabetic effect, obesity control, anti-tumor, and anti-inflammatory, called as functional sugars. For this reasons, functional sugars have been numerous attention widely in synthetic, cosmetics, pharmaceutical, food, and flavor industries.

- D-Psicose (D-allulose)), a kind rare sugar, existed in nature as monosaccharides but are present in only limited quantities. D-Psicose has been attracted due to zero calories, while it has 70% relative sweetness compared with sucrose. Since various specific biological functions also have been studied, including reducing intra-abdominal fat accumulation, protecting pancreas beta-islets and improving insulin sensitivity, D-psicose has been considered as substitute of sugar for obesity and diabetes patients. It recently have been applied in various commercial food industry including beverages, yogurt, ice cream, and baked goods.

- Sugar alcohols such as mannitol, sorbitol, xylitol, erythritol, and isomalt are naturally found in fruits and vegetables and some bacteria, fungi, yeasts, and algae. Sugar alcohols are widely used in food and pharmaceutical industries because of their attractive physicochemical properties. D-Mannitol, a valuable sugar alcohol, has similar sweetness compared with sucrose, but only has 1.6 kcal/g. Due to its low glycemic index, it has been considered as low-cariogenic sweetener, particular in diabetic patients. Low hygroscopicity and cooling effect of mannitol make it useful as food addictive. Diuretic and pressure lower function of D-mannitol makes it useful as medication too.

- α-D-Glucosylglycerol (GG) ), compatible solutes accumulated by some plant, algae, and bacteria in adaptations to salt or desiccation stresses. GG has been received interest for high-grade moisturizer recently. It affects hydration levels in the mammalian skin epidermis by increasing expression level of aquaporins (AQP3), and decrease water loss in dry-stressed skin. Additionally, GG has 55% sweetness of sucrose but it partially metabolized, making it possible to use as an alternative sweetness for obesity and diabetes. Non-cariogenic capacity and high potential of prebiotic properties, also suggesting GG as promising functional food for human healthcare.

Keywords: 3rd Generation Sugars, Sugar Alcohols, Psicose, Allose, Mannitol, Pinitol, Chiroinocitol, Glucosylglycerol

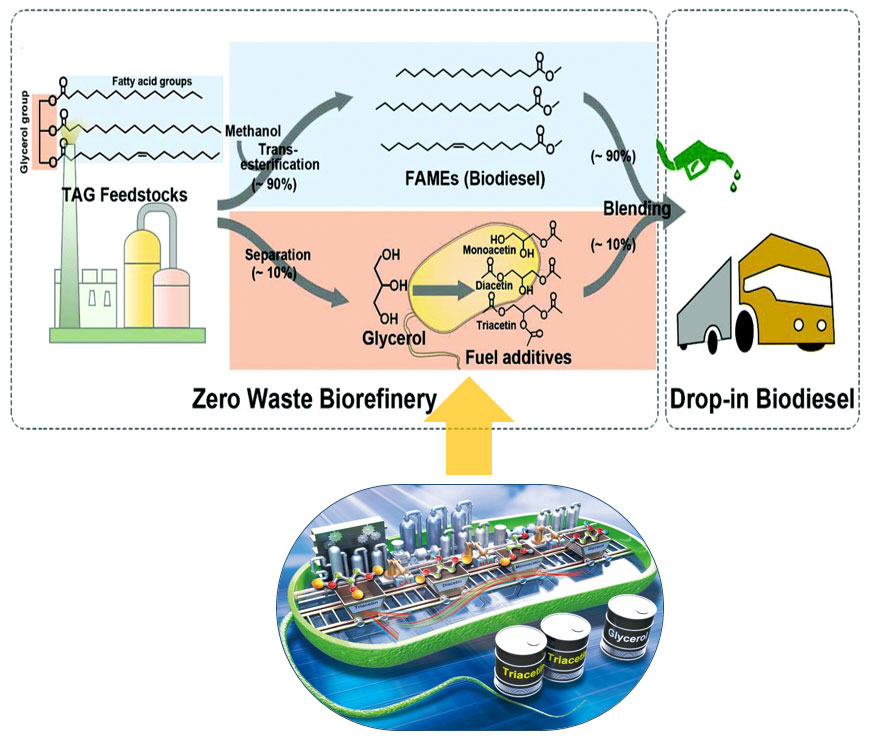

Carbon Neutral Biorefinery

Biorefinery is a promising way to generate different kind of valuable products with short processing time. Zero Waste Biorefinery, could be also called as Carbon Neutral Biorefinery is a new technology that conserves and recovers all resources to eliminate the volume of waste materials produced by industry that would be otherwise be burned or buried. The goal of Zero Waste Biorefinery is thus to process and convert waste streams produced at various industrial sites into valuable chemical compounds, thereby closing the production loop with no net waste. Zero waste biorefineries could play a key role in the sustainable economic system and the environment. This technology uses resources in a more efficient way, thus diminishing the overall generation of wastes and enabling the recovery of unavoidable discards from the industrial sites as the source of resources for the generation of new valuable products. Glycerol is a by-product accompanying the production of biodiesel. It is reported that 10 lb of crude glycerol is generated for every 100 lb of biodiesel produced by trans-esterification of vegetable oils or animal fats. In recent years there has been growing interest in biorefinery industries towards the utilization of surplus glycerol. Triacetin, also called glycerin triacetate, is used as a fuel additive to improve the freezing and viscosity properties of biodiesel as well as an antiknock agent which can reduce engine knocking in gasoline. Engine performance can be significantly improved by blending 10% triacetin with biodiesel. Bioconversions of surplus glycerol into triacetin along with biodiesel production could serve as a complete on-site Zero Waste Biorefinery. Here, we metabolically engineered Escherichia coli for the production of triacetin using surplus glycerol from the biodiesel refinery’s site. Our strategy of Zero Waste Biorefinery closing the loop by utilizing side-streams from the biodiesel industry and thus could benefit the biodiesel industry by utilizing waste glycerol that is generated during biodiesel production.

Keywords: Zero Waste Biorefinery, Carbon Neutral Biorefinery, Consolidated Bioprocess, Acetin, Glycerol, Biofuel, Biodiesel

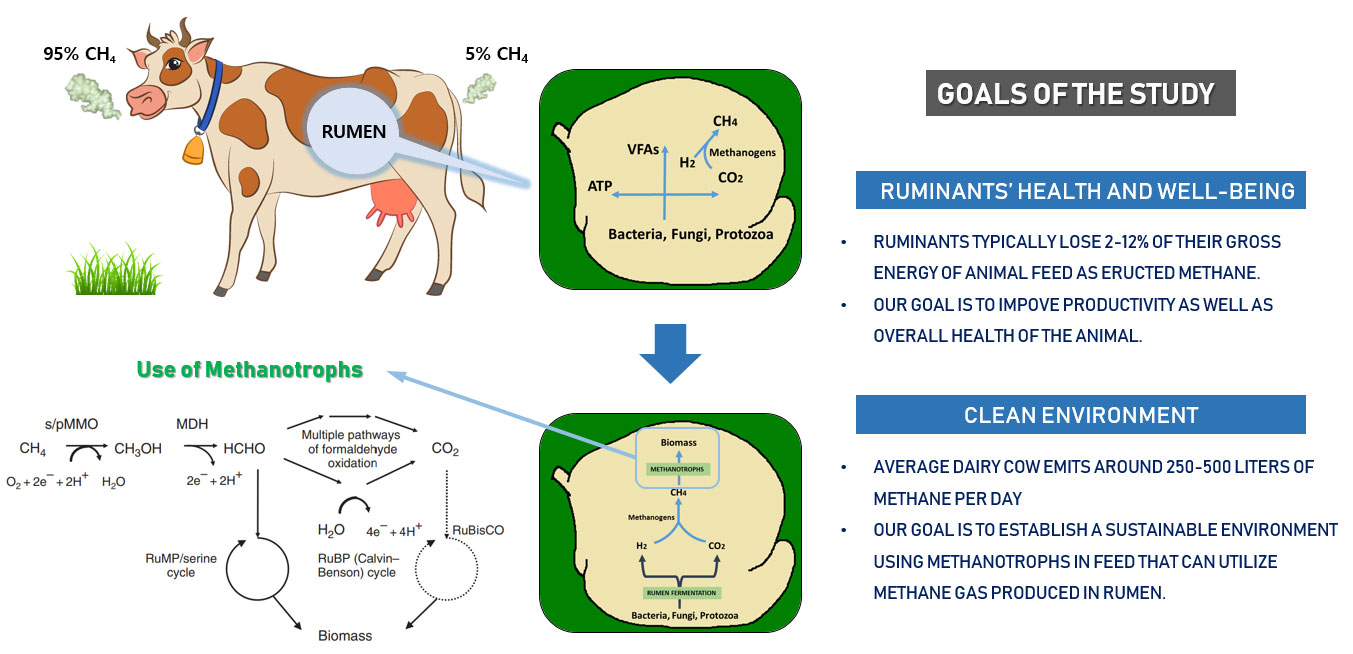

Microbiome: Rumen

Methane is a potent greenhouse gas due to its ability to trap infrared radiation in the atmosphere thereby increasing the global temperature. It is also estimated that the demand for milk product and meat will increase to 1.04 million tons and 465 million tons by 2050, respectively. It is a growing concern that the population growth, increased lifespan and improving economic prosperity might increase the global demand for animal products which subsequently, will elevate the greenhouse gas production and inevitably speed up global warming. Therefore, great deal of attention has been given towards enteric methane emission from the ruminants. Methane oxidizing bacteria (MOB) are present in both aerobic and anaerobic environments where these bacteria oxidize methane as a sole carbon and energy source. Several groups have demonstrated the occurrence of methane oxidation and some have successfully isolated MOB from various ruminants. However, very limited studies have been done so far in order to use MOB as a probiotic in rumen to reduce methane emission. We strive to improve the overall productivity of the animal and achieve a sustainable environment using methanotrophs as probiotic.

Keywords: Greenhouse effect, Ruminants, Methane, Methanotrophs, Methane Oxidizing Bacteria (MOB), Microbiome

Microbiome: Cosmetics

Air Proteins

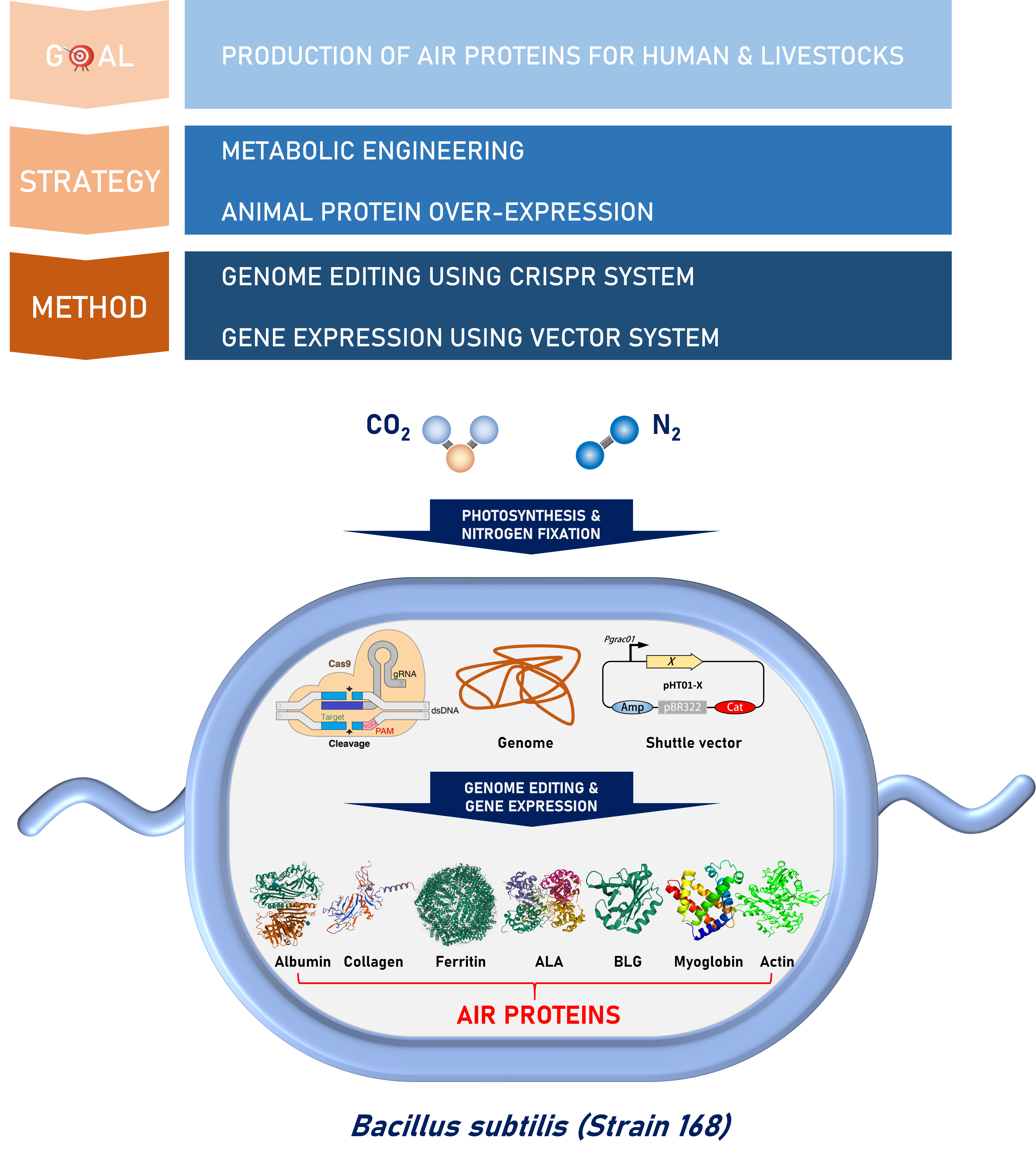

We are working on engineering a bacterial strain, Bacillus subtilis 168 for the production of proteins, using air (nitrogen and carbon dioxide) as nutrients sources. Several candidates including ovalbumin, collagen, ferritin, β-lactoglobulin, α-lactalbumin, and myoglobin were selected for expression in B. subtilis 168, using a shuttle vector, pHT01, and subsequent chromosomal integration. In order to improve industrial applicability, the B. subtilis strain will also be engineered by CRISPR-Cas9 system to deactivate genes that are responsible for smell production and extracellular protein secretion such as amyE etc.

Keywords : Production of air proteins, Metabolic engineering, Bacillus subtilis, Ovalbumin, Collagen, Ferritin, β-Lactoglobulin, α-Lactalbumin, Myoglobin